Nitration

Nitration occours when there is sufficient heat and pressure in the combustion chambers of the engines which breakes the atmospheric nitrogen molecule down to two atoms which thereafter react with oxygen to form Nitrous Oxides (NOx). This creates a huge issue for some engines, mainly natural gas engines as they operate at higher combustion temperatures and therefore high Nitrous Oxides (NOx) are formed. Through normal blow-by, when nitrogen oxide products enter the lubricant, the react with the moisture and become acidic in nature and rapidly accelerate the oxidation rate of the oil.

If the oil is exposed to severe nitration conditions, the nitration products in the oil will cause:

- Increase in viscosity due to thickning of the oil

- Increase in the acidity of the oil resulting in increase in Acid Number (AN)

- Increase in insolubles. This includes varnish or lacquer in hot areas of the engine, and sludge in cooler areas of the engine which may lead to ring sticking and filter plugging, respectively

- increase in blow-by which will lead to top-end wear

Testing of Nitration

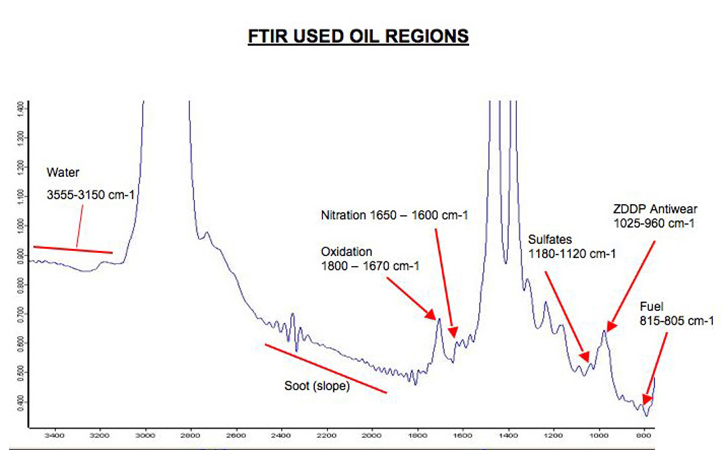

The testing of Nitration is done in our laboratory by using (FTIR) Fourier transform infrared spectrometer, which can be coupled with Acid Number Test and Viscosity to determine the extent of nitration and degradation of the oil.

Method of Testing

As per ASTM E2412 & ASTM D7624 : Standard Test Method for Condition Monitoring of Nitration in In-Service Petroleum and Hydrocarbon-Based Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR) Spectrometry.

Testing Equipment used by us in our laboratory: PerkinElmer make FT-IR Spectrometer model Spectrum 65.

A typical FTIR graph in which Nitration is detected and determined