Particle Count

If your oil is clean it means your system / machinery is clean. Hence the importance of clean oil is undisputed and cannot be over emphasized. Therefore Particle Count is considered by most to be the single most important factor for testing of Hydraulic Oils, used oils, fluids and liquids.

Particle count nowdays is mainly tested and representated by two methods. The most common accepted method is ISO 4406:99 while the other standard used is NAS 1638.

What is contamination and how does it happen ? Dust which is present in the air, wear debris in the machinery, air pollutants like soot, carbon deposits, sucking up of dirt in the system and / or any deposits which can enter or become the cause of contamination of the oil or liquid or fluid.

What are the advantages of Particle Counting ?

Particle counting offers huge benefits over a large multitude of issues like :

- Torn filters or filters which are redundant

- Clogged filters

- Determines time to change the filter

- Determines filter performance

- Confirmation if new filter is in optimum condition

- Checks lubricant cleanliness

- Checks if maintenance is required

- Detects wear in the system

- Detects corrosive wear, abrasive wear and abnormal wear

- Identifies if Ferrographic analysis and testing is required

- Mainly it determines if target oil cleanliness is achieved

An outline of both the methods is given as under :

ISO 4406 – ISO CLEANLINESS CODE

ISO 4406 determines the counts of particles which indicates the different size of the particles in 3 different size groups and gives the results as :

First part group / Second part group / Third part group

Let’s say : 19/13/9

- First part group which is - 4 µm or larger per mL of fluid

- Second part group which is - 6 µm or larger per mL of fluid

- Third part group which is - 14 µm or larger per mL of fluid

NAS stands for 'National Aerospace Standard'. It indicates how clean or dirty a oil is. It counts the number of microscopic particles per 100 ml oil sample. It further also indicates the different size of the particles as per micron in five different groups.

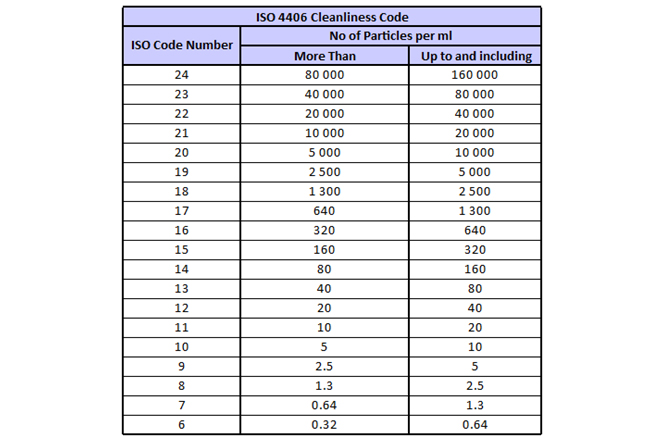

The chart of grading of the oil based on the number of particles per mL of the oil or fluid or liquid is as under :

Instrument used for ISO 4406 – ISO Cleanliness Code determination by us in our laboratory is HIAC PODS+. Any liquid of either low or high viscosity can be tested and the report data corresponding to ISO 4406 is obtained.

NAS VALUE - 1638

NAS stands for 'National Aerospace Standard'. It indicates how clean or dirty a oil is. It counts the number of microscopic particles per 100 ml oil sample. It further also indicates the different size of the particles as per micron in five different groups.

NAS 1638 represents the counts of particles in five size groups:

- 5 to 15 microns per 100 mL

- 15 to 25 microns per 100 mL

- 25 to 50 microns per 100 mL

- 50 to 100 microns per 100 mL

- >100 microns per 100 mL

The microscopic contaminants or very minute particles in the oil or fluid or liquid are counted by the instrument. This is useful not only for hydraulic oils or aerospace machinery but in various industries.

The contamination level is classified by NAS Value by a number which ranges from 00 (which is the cleanest) to 12 (which is the dirtiest).

The chart of grading of the oil based on the number of particles per 100 mL of the oil or fluid or liquid is as under :

Instrument used for ISO 4406 and NAS Value determination by us in our laboratory is HIAC PODS+. Any liquid of either low or high viscosity can be tested and the report data corresponding to ISO 4406 or NAS 1638 is obtained.